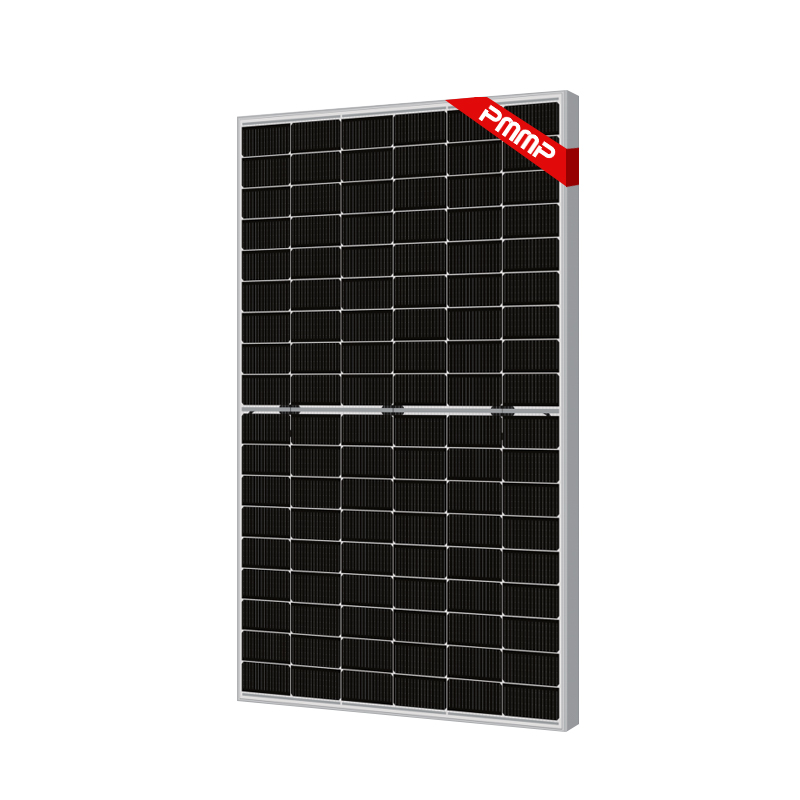

Solar Dual Glass Mono 108cells 430W Solar Panels

Product Introduction

The bifacial ratio of N-type battery modules reaches more than 80%, which is 15% higher than that of P-type cells; the TOPCon process does not require backside laser grooving, and has less stress and stronger crack resistance than BiPERC cells; the high open circuit voltage of N-type TOPCon cells, Therefore, the temperature coefficient is lower and the power generation is higher.

Product Performance

Product Features

1. Double-sided use of N-type battery modules, the conversion rate is as high as 80%.

2. Adopting contact contact technology to block minority carrier transmission and reduce contact loss.

3. Using ultra-thin polysilicon technology to increase current density, increase internal reflectivity, and improve back metal contact performance.

4. SMBB is an upgraded version of MBB technology, which uses thinner grid lines to achieve less occlusion and shorter conduction distance.

5. The front of the cell adopts gradient dielectric film technology to achieve passivation, anti-reflection, extinction and other effects, and to achieve anti-PID function.

6. Using battery non-destructive cutting technology to achieve no mechanical damage, high efficiency, less pollution and other effects.

7. The half-cell technology is adopted to halve the current and reduce the resistance; increase the cell spacing to make the reflection uniform.

8. The use of steel frame instead of aluminum frame can improve the matching of frame expansion coefficient and glass, and reduce the risk of sealant failure.

9. The fluorine-free backsheet can support the green recycling of photovoltaic modules. PO film and PET have double-layer water vapor barrier function, which can meet the requirements of 25 years of use.

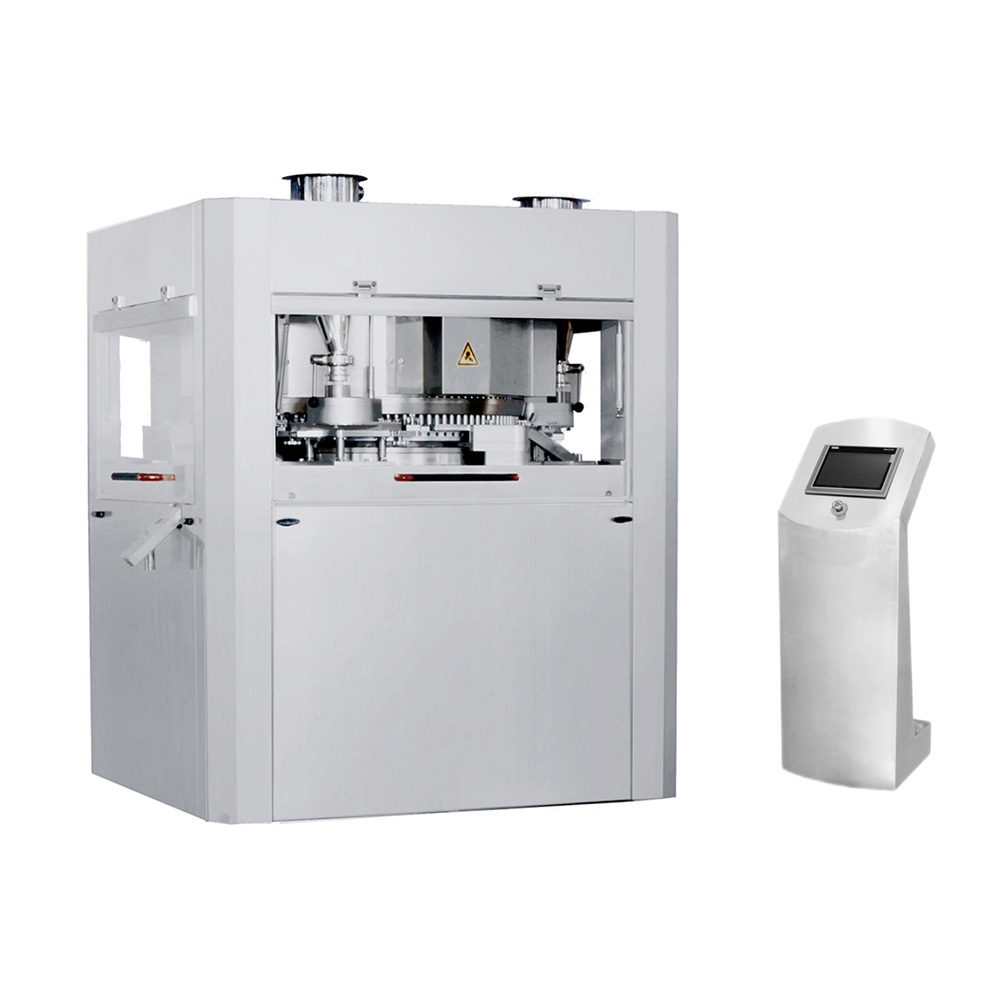

R & D And Production

Fully intelligent management of production. 3 times 100% visual inspection: before lamination, after lamination, before packaging. 3 times 100% EL inspection: battery string, before lamination, before packing. 100% dielectric withstand voltage test: withstand voltage, insulation, grounding.