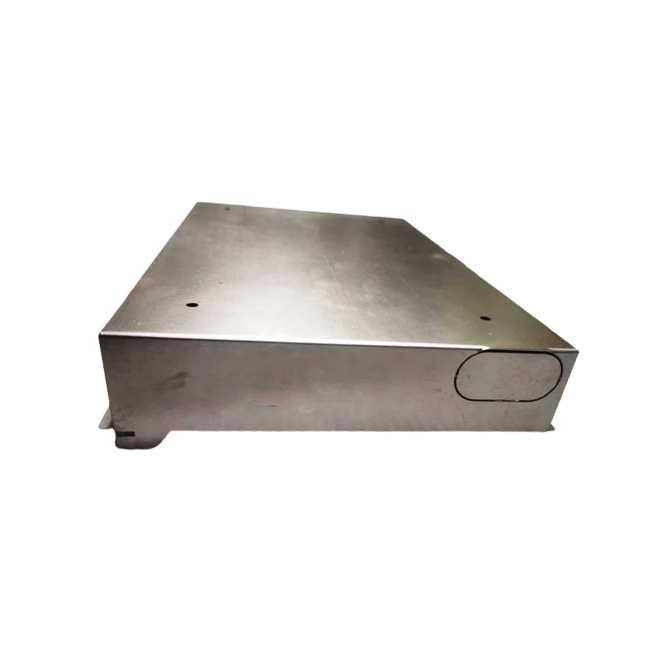

Sheet metal fabrication service galvanized sheet stamping parts

Video

Products Advantages

As a sheet metal fabrication prototype company specializing in sheet metal bending and providing metal stamped services for sheet metal prototypes, we focuse on prototype and small batch production and we have the following advantages:

1.Professional sheet metal processing capabilities: We have a high-quality technical team who are proficient in various sheet metal processing technologies and can quickly produce high-quality prototype sheet metal parts. Our production equipment also ensures high-efficiency production and processing quality.

2. Flexible production mode: We focus on small batches and customized production, and can quickly produce according to customer needs to continuously improve customer satisfaction.

3.A variety of surface treatment options: We have a variety of surface treatment technologies, and can provide products with various surface treatment methods such as galvanizing, spraying, and electroplating to meet the needs of different products.

4.Quick response and timely delivery: Our production and logistics have been optimized to be able to quickly respond to customer needs while ensuring timely delivery.

5. Competitive prices: Our advantages in purchasing channels and production capacity ensure the rationality of product prices and provide customers with cost-effective products and services.

Packaging and Delivery

The packaging and delivery of sheet metal products is an important link, we will follow the steps below:

1. First inspect the product to ensure that the product quality meets the requirements.

2. Use appropriate packaging materials, and choose appropriate cartons, wooden boxes or pallets, etc. according to the size and weight of the product.

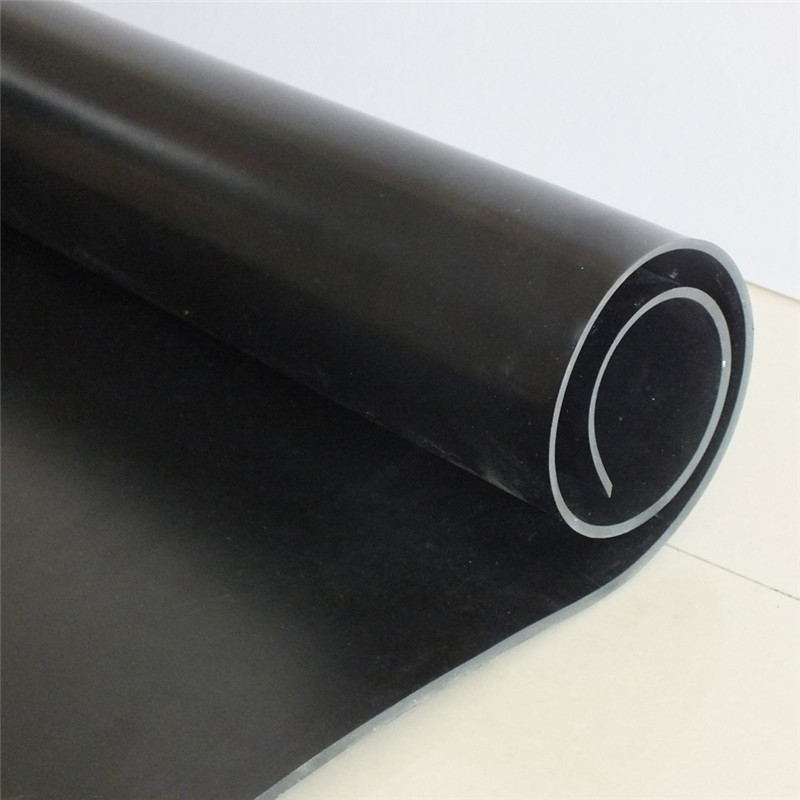

3. Fill the packing box with an appropriate amount of cushioning materials, such as foam plastics, air bags, foam paper, etc., to protect the product from damage, impact or extrusion.

4. For fragile and heavy products, we will add reinforcement materials to ensure the safety of product transportation.

5. Indicate on the packing box, including product name, quantity, specification, weight, transportation direction, precautions, etc.

6. Adopt safe and reliable transportation methods such as express delivery and logistics to ensure that the products are delivered to the designated address of the customer in time, and provide the delivery notice and waybill number at the same time. To sum up, we will try our best to ensure that every link of product quality, packaging and logistics meets high standards, and provide customers with fast, safe and satisfactory services.

If you need further rapid prototyping techniques, such as CNC machining prototype, 3d printing, we also can meet your requirements. Pls no hesitact to contact us today to get immediate quote for your projects!