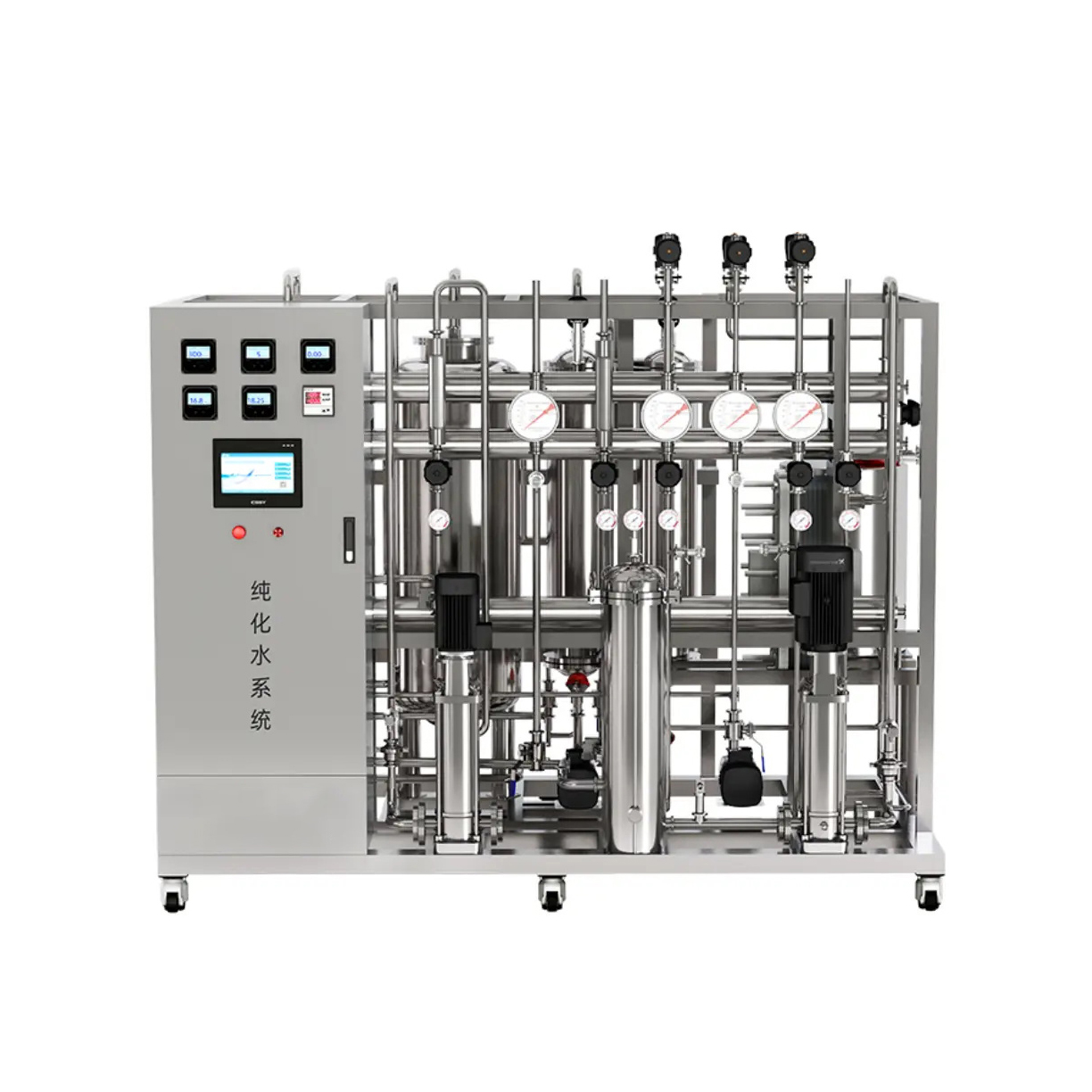

Purified Water Preparation System CH-500L

Product Description

Purified water preparation system takes drinking water as raw material and “purify” the raw water into purified water that meets the requirements of Chinese Pharmacopoeia, U.S. Pharmacopoeia and International Pharmacopoeia through pre-treatment, membrane filtration, ion exchange and deionization. The purified water preparation system has two kinds of water treatment capacity: 500L/H and 1000L/H. Users can choose according to different needs or combined use. The system adopts RO-RO-EDI process, closely filtered and purified to ensure stable and high quality water quality. CSSY equips the purified water preparation system with imported filter elements, valves and other precision accessories to create high-quality purified water preparation machinery. SSY-CH-500L series purified water preparation system water quality in line with the national pharmacopoeia and the U.S. FDA water purification standards, but also in line with the GMP certification requirements. Because the equipment has the advantages of high efficiency and energy saving, it can save a lot of investment for users in the long run.

Product Features

1. According to the water quality of the customer’s area and the site of the substantive needs of the design of the purified water preparation system process, to ensure that the user to use the equipment to maximize the performance.

2. Online monitoring function can accurately monitor the EDI, conductivity and PH value and other information and display it through the online monitoring table.

3. Adjust the PLC programming according to the customer’s needs, intelligent control system, more close to the customer’s operation and maintenance.

4. The system is installed with pneumatic diaphragm valve and sampling valve, which is easy to dismantle. Sampling valve in the water quality problems can also be graded for aseptic sampling, fast and safe, but also to ensure the health of the equipment.

5. The front and rear sections of the equipment are equipped with pasteurization, reducing the possibility of contamination of water and equipment.

6. Configuration of sanitary centrifugal pumps, eliminating water residue, reducing health dead ends, control system of bacterial growth.

Write your message here and send it to us