We are here to help with customization options to meet your specific manufacturing needs.

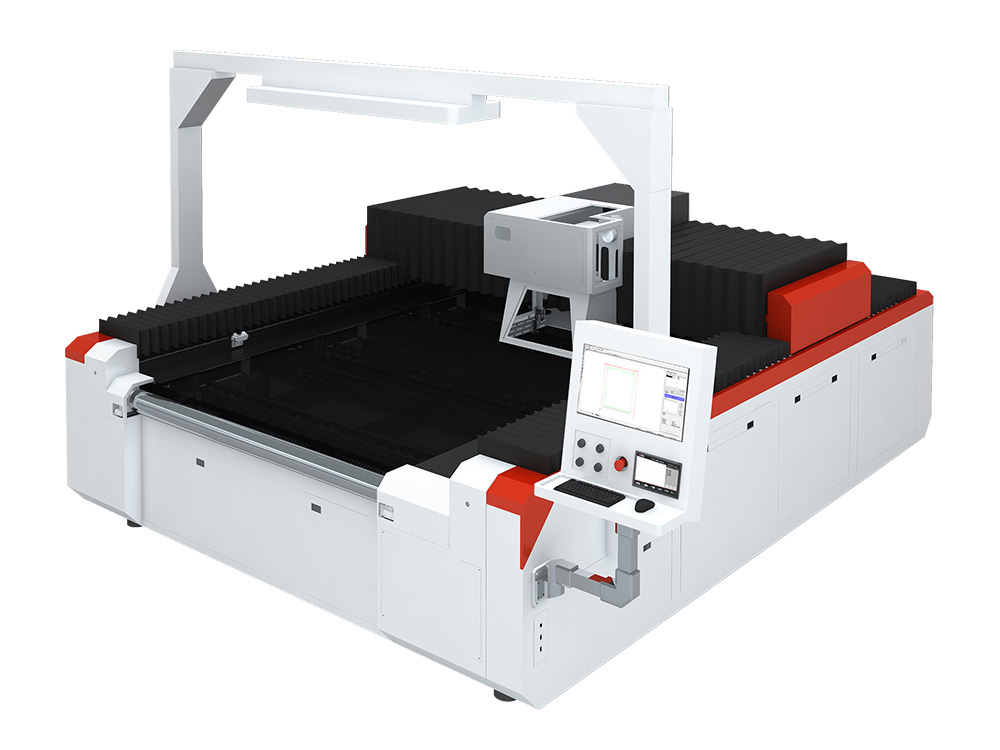

High Speed Laser Perforation and Cutting Machine with Camera

High Speed Laser Perforating and Cutting Machine with Vision System

This laser cutting system combines the precision of Galvo and the versatility of Gantry, offering high-speed performance for a diverse range of materials. With a processing format of 1700mm x 2000mm (customizable on demand), an optional auto-feeder, and laser power options ranging from 150W to 300W, the machine ensures powerful and customizable performance.

The integrated camera systems, alongside features like a gear and rack drive structure, automatic switching between galvanometer and gantry modes, and a conveyor system, contribute to a seamless and efficient workflow.

This machine is designed for multifunctionality, efficiency, and precision in every detail. Ideal for the fashion industry and digital printing fabric applications, this innovative laser solution elevates manufacturing capabilities to new heights.

Highlights of the Machine Structure

The Galvo & Gantry integrated design allows the machine to seamlessly transition between two distinct motion control systems: the galvanometer system and the gantry system.

1. Galvanometer System:

The galvanometer system is known for its high-speed and precision in controlling the laser beam. It employs a set of mirrors that can rapidly reposition to direct the laser beam across the material surface. This system is exceptionally effective for intricate and detailed work, providing swift and accurate laser movements for tasks such as perforating and fine cutting.

2. Gantry System:

On the other hand, the gantry system involves a larger-scale motion control mechanism, typically consisting of a gantry structure with a moving laser head. This system is advantageous for covering larger surface areas and is well-suited for applications that require broad, sweeping movements.

Automatic Switching Mechanism:

The brilliance of the automatic switching feature lies in its ability to seamlessly transition between these two systems based on the specific requirements of the job at hand. This feature is often software-controlled and can be programmed to engage the galvanometer system for intricate detailing and then switch to the gantry system for broader, less detailed tasks, all without manual intervention.

Benefits:

- • Versatility: The machine can adapt to a wide range of applications, from intricate designs to larger, more expansive cutting tasks.

- • Optimized Efficiency: The automatic switching ensures that the most suitable motion control system is employed for each part of the job, maximizing efficiency and reducing processing time.

- • Precision and Speed: Combining the strengths of both systems, this feature allows for a harmonious balance between precision and speed in laser processing.

MACHINE FEATURES

Golden Laser’s High-Speed Galvo & Gantry Laser Machine – your partner in precision and efficiency.

Rack and Pinion Drive

Precision meets speed with our robust rack and pinion drive structure, ensuring high-speed bilateral synchronous drive for efficient perforating and cutting processes.

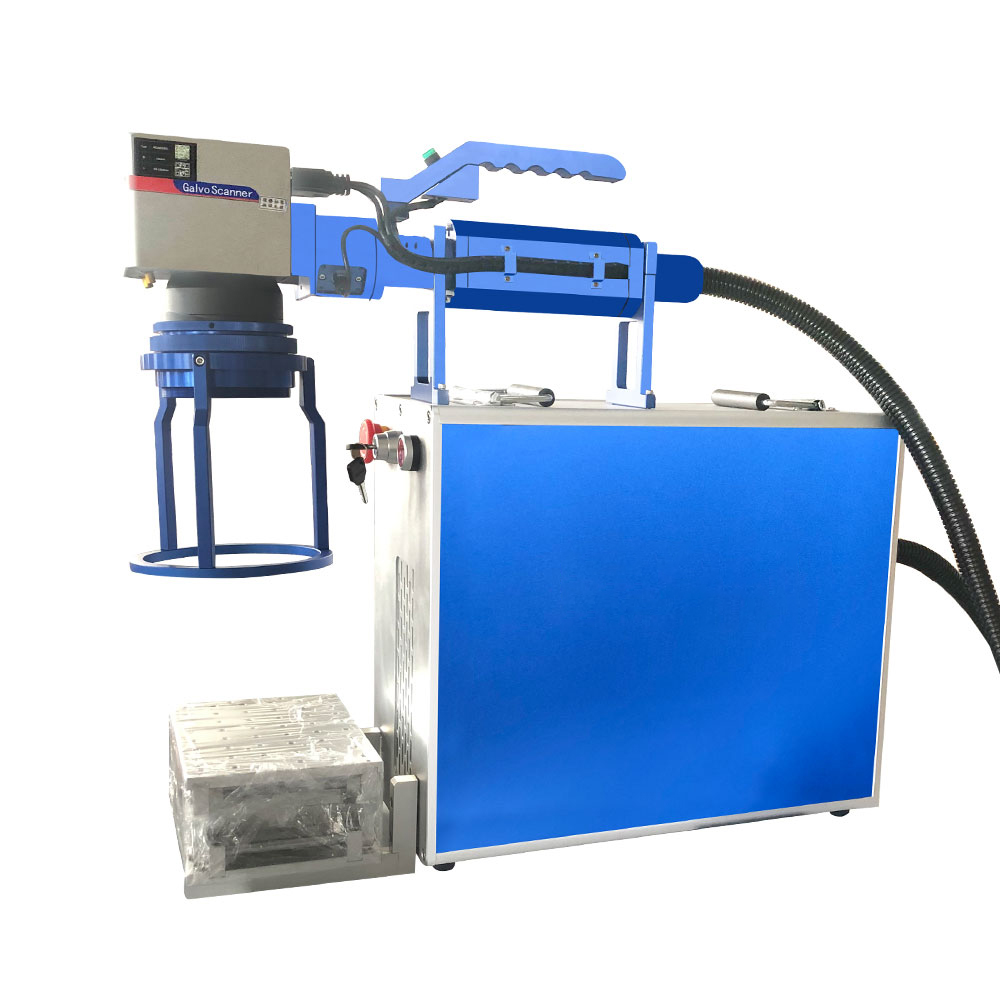

3D Dynamic Galvo System

Experience unmatched accuracy and flexibility with our advanced three-axis dynamic galvanometer control system, delivering precise laser movements for superior results.

Vision Camera System

Equipped with state-of-the-art high-definition industrial cameras, our machine ensures advanced visual monitoring and precise material alignment, guaranteeing perfection in every cut.

Motion Control System

Benefit from cutting-edge technology of a closed-loop motion control system with with independent intellectual property rights, ensuring superior performance and reliability.

Follow-Up Exhaust Device

Keep your workspace clean and efficient with our follow-up exhaust device, swiftly and cleanly removing smoke from the cutting process.

Reinforced Welded Bed

The machine features a reinforced welded bed and large-scale gantry precision milling, providing a stable foundation for accurate and reliable laser processing.

Application

Golden Laser’s High-Speed Galvo & Gantry Laser Machine – Ideal for a wide range of industries, including:

1. Sportswear and Activewear:

Specifically designed for creating ventilation holes and intricate patterns on sportswear, gym apparel, and leggings.

2. Apparel, Fashion and Accessories:

Perfect for precision cutting and perforation of fabric for clothing items, ensuring clean edges and intricate designs.

3. Leather and Footwear:

Ideal for perforating and cutting leather used in the production of shoes and other leather goods like gloves.

4. Decorative Items:

Precision cutting for creating intricate patterns on decorative items such as tablecloths and curtains.

5. Industrial Fabrics:

Ideal for cutting and perforating fabrics used in automotive interiors, fabric ducts an other technical textiles.