Gypsum Board Line

Advantage of Gypsum Board Line

After board out from dryer, going through 2# cross conveying system, the unquality boards(around 3-5%) will be sent to 3rd cross conveyor sytem to stack and used to make dunnages or other use; while qualified boards comes to automatic sawing system.

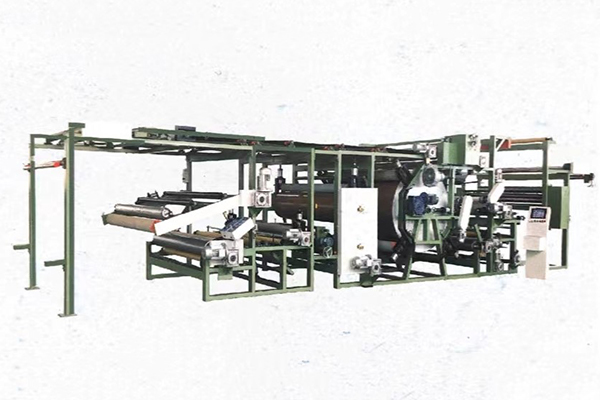

Edge-sawing&sealing machine composes of auto alignment system, auto edge cutting system, crushing system, auto sealing system and impulse bag filter. It can achieve 1800mm ~ 3600mm precisely fixed length and cutting edge. Before cutting, the boards are aligned by alignment system to ensure the two boards’ ends are aligned, then comes to cutting system. After cutting at the width direction, the cut-off strips are crushed into tiny pieces by crushing system, and sucked by impulse bag filter, realizing no pollution during production process; After cutting, boards moves to automatic sealing system, which will cover board edges with edge tape at both end. The edge tape also can print factory brand information, ensure of nice appearance and advertising.

Brief Description of China Gypsum Board Line:

1. Annual output:

5 million to 10 million sqm(based on thickness of 9.5mm gypsum board)

2. Working time: 24hours/day and 300 working days/year

3. Raw material: Gypsum powder, shielding paper, modified starch, foaming agent, glue

4. Fuel: Natural gas, LPG, diesel, coal or heavy oil

5. Product quality and specification:

1) The product is in compliance with National Standard GB/T9775-2008 or equivalent international standard

2) Product specification:

Length: 2400mm~3600mm

Width: 1200mm or 1220mm

Thickness: 8mm-20mm

6. Main technology:

The production line adopts special designed direct hot air stove heating system or Duel fuel hot air stove system

- Manpower for production

|

No. |

Working position |

No. of people |

Remarks |

|

I |

Main workshop | ||

|

1 |

Foreman |

1 |

|

|

2 |

Material proportion |

1 |

|

|

3 |

Technological controller |

1 |

Also in charge of operating dryer |

|

4 |

Shaping station (paper supply, mixing, shaping) |

4-5 |

|

|

5 |

1# horizontal conveyor operator |

1 |

|

|

6 |

2# horizontal conveyor operator |

4 |

|

|

7 |

Stacking |

2 |

|

|

8 |

Packing |

2 |

Depent on actual situation |

|

9 |

Forklift driver |

1 |

Depent on actual situation |

|

II |

Mechanic and electrician | ||

|

10 |

Mechanic |

2 |

|

|

11 |

Electrician |

1 |

Always stay at 1# horizontal conveyor station |

|

III |

Laboratory | ||

|

12 |

Chemical analyst |

1 |