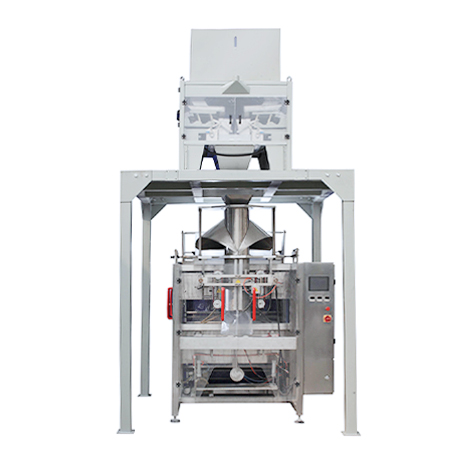

Fertilizer Bagging Machine, Fertilizer Bagging Plant For 20kg To 50kg Fertilizer

General Technical Specification

| Name | 50 Kg Rice Packing Machine, 25kg Bag Flling Machine,Automated Bagging Line , Bag Packing Machine Price, Animal Feed Packaging Machine,50 Kg Bagging Machine , Automated Bag Packaging Machinery |

| Bagging weight range | 20- 50kg |

| Packing speed | 8-13bags/min |

| Bag dimension | width:400- 520mm; length: 550-950mm |

| Air consumption | 1Mpa |

| Gas consumption | 3m³/min |

| Power voltage | 220/380VAC three phase, 50HZ |

| Power | 8Kw |

Working Process

1. Pre-packed Empty Bags

Place 2-3 stacks of empty bags at the same time to provide bags for the packaging machine

2.Take an Empty bag

Back sucking mechanism sucks the bottom of the bag with negative pressure, while the ruler-up type back transmission structure fastens the mouth and transmit it to the bag opening station.

3.Open Empty bag

The bag opening mechanism simultaneously sucks the positive and negative sides of the bag mouth with negative pressure. The affective pressure sucks the bag mouth and is it and then the “insert knives” structure located on both sides of the material discharge port is inserted into the badmouth by shaft rotation and spread to both sides.

4.Supply Empty bag

transfer the empty bag to the bag clamping mechanism by lifting up the knife arm to complete the bag supplying operation. The bag clamping mechanism clamps both sides of the bag to prevent dust from overflowing.

5.Material filling the bag clamping detection device ensures the reliability of the bag supplying, After the detection is completed, the PLC will give a signal to the automatic weighing unit. then the material in the weighing unit will be discharged into the packaging bag. During the fueling process, perform bottom vibration operation. At the same time, through the external dust removal interface, the dust formed by the material is pumped away in the discharge process.

6.Holding bag and Stitching Sewing & Heat Sealing

After the material filing is completed, the bag mouth is clamped horizontally through the bag-holding conveying mechanism, then the bag horizontally conveyed to the outside entry mechanism. and the bag is conveyed to the stitching sewing & heat sealing station for automatic stitching sewing or heat sealing.

Product Characteristics

1) Easy to operate and use

2) Bag-clamp equipment is advanced, material can be filled automatically

3) Fill material system has material-stop equipment, accuracy high control, work parts all use imported parts, stable and reliable with sewing machine.

4) Heat Sealing machine optional.

General Technical Specification

| Name | 50 Kg Rice Packing Machine, 25kg Bag Flling Machine,Automated Bagging Line , Bag Packing Machine Price, Animal Feed Packaging Machine,50 Kg Bagging Machine , Automated Bag Packaging Machinery |

| Bagging weight range | 20- 50kg |

| Packing speed | 8-13bags/min |

| Bag dimension | width:400- 520mm; length: 550-950mm |

| Air consumption | 1Mpa |

| Gas consumption | 3m³/min |

| Power voltage | 220/380VAC three phase, 50HZ |

| Power | 8Kw |

Working Process

1. Pre-packed Empty Bags

Place 2-3 stacks of empty bags at the same time to provide bags for the packaging machine

2.Take an Empty bag

Back sucking mechanism sucks the bottom of the bag with negative pressure, while the ruler-up type back transmission structure fastens the mouth and transmit it to the bag opening station.

3.Open Empty bag

The bag opening mechanism simultaneously sucks the positive and negative sides of the bag mouth with negative pressure. The affective pressure sucks the bag mouth and is it and then the “insert knives” structure located on both sides of the material discharge port is inserted into the badmouth by shaft rotation and spread to both sides.

4.Supply Empty bag

transfer the empty bag to the bag clamping mechanism by lifting up the knife arm to complete the bag supplying operation. The bag clamping mechanism clamps both sides of the bag to prevent dust from overflowing.

5.Material filling the bag clamping detection device ensures the reliability of the bag supplying, After the detection is completed, the PLC will give a signal to the automatic weighing unit. then the material in the weighing unit will be discharged into the packaging bag. During the fueling process, perform bottom vibration operation. At the same time, through the external dust removal interface, the dust formed by the material is pumped away in the discharge process.

6.Holding bag and Stitching Sewing & Heat Sealing

After the material filing is completed, the bag mouth is clamped horizontally through the bag-holding conveying mechanism, then the bag horizontally conveyed to the outside entry mechanism. and the bag is conveyed to the stitching sewing & heat sealing station for automatic stitching sewing or heat sealing.

Product Characteristics

1) Easy to operate and use

2) Bag-clamp equipment is advanced, material can be filled automatically

3) Fill material system has material-stop equipment, accuracy high control, work parts all use imported parts, stable and reliable with sewing machine.

4) Heat Sealing machine optional.