Factory Supply Aluminum Alloy 1060 Anodized Aluminum Extrusion Profile

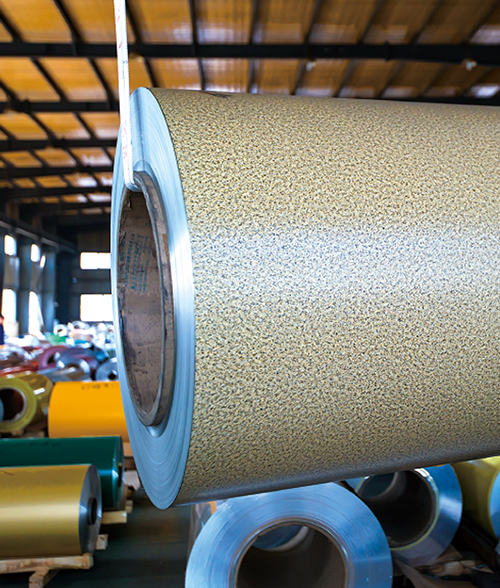

Aluminum alloy 1060 is a high-purity aluminum alloy that is characterized by its excellent formability, good corrosion resistance, and high thermal and electrical conductivity. It is particularly suitable for applications that require high ductility and reflectivity, making it an ideal choice for many different industries.

Product Description

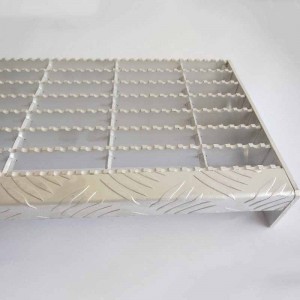

Our factory supply aluminum alloy 1060 anodized aluminum extrusion profile is a high-quality, versatile, and durable material that is widely used in various industries for its excellent properties. It is a type of aluminum extrusion profile that has been anodized to enhance its corrosion resistance, durability, and aesthetic appeal. This product is designed to meet the diverse needs of our customers and can be customized to specific requirements.

Feature

Our aluminum alloy 1060 anodized aluminum extrusion profile boasts numerous advantages, including:

- Corrosion and wear resistance: The aluminum alloy 1060 is specifically formulated to offer superior corrosion and wear resistance, making it an ideal choice for many applications.

- Anodized surface treatment: The anodized surface enhances the natural surface of the aluminum profile, while also providing an additional layer of protection against weathering, scratches, and other types of damage.

- Versatile applications: This aluminum profile is highly versatile and can be used in a variety of applications, including furniture, automotive, construction, and electronics.

Application

The versatility and durability of our aluminum extrusion profile make it suitable for a wide range of applications. It is commonly used in the construction of structures, such as window frames, door frames, and curtain walls, due to its lightweight nature and corrosion resistance. In addition, it is widely utilized in the manufacturing of heat sinks, electrical enclosures, and automotive components due to its excellent thermal and electrical conductivity. Its aesthetic appeal also makes it a popular choice for interior design elements, furniture, and retail displays.

Company Advantages

In , we are committed to providing our customers with the highest quality products and services, including:

- One-stop aluminum service: We offer a wide range of aluminum products and services, including extrusion, fabrication, and finishing.

- High-quality products: We use only the highest quality materials and manufacturing processes to ensure that our products meet the highest standards of quality and durability.

- Fast delivery times: We pride ourselves on our ability to deliver products quickly and efficiently, helping our customers to achieve their goals on time and on budget.

our customers

Our primary focus is ensuring customer satisfaction. Established in 1993, ZHONGLIAN/ was built on the principle that high-quality products and exceptional customer service would stand the test of time. More than 30 years on, we remain committed to the idea that our customers’ satisfaction shapes our business practices. Throughout the years, we have collaborated with clients from over 70 countries and more than 200 regions worldwide.

Basic Information

| Product Name | Factory Supply Aluminum Alloy 1060 Anodized Aluminum Extrusion Profile |

| Aluminum Alloy | 1000 series, 1060 |

| Suitable systems Types | electric heating pipes, oil tanks, gasoline or lubricating oil pipes, conductive materials, etc |

| Surface Treatment | mill finished, anodized, wood grain, power coating, sand blasting, electrophoresis, brushed, polishing, etc |

| CNC Deep Processing | cutting, drilling, machining, punching, bending, tapping, etc |

| Certifications | CE, ISO, SGS, TUV, ROHS |

| Package | wooden shelf,actual reimbursement |

| MOQ | 500KG for each profile |

| Delivery Time | Mold developing and sample conformation is 12-15 days, then production duration is 15-25 days after receipt of deposit from buyer. |

| Payment Terms | 30% deposit before production, and balance before shipment. |

| Port | Shenzhen, Guangzhou |

Write your message here and send it to us