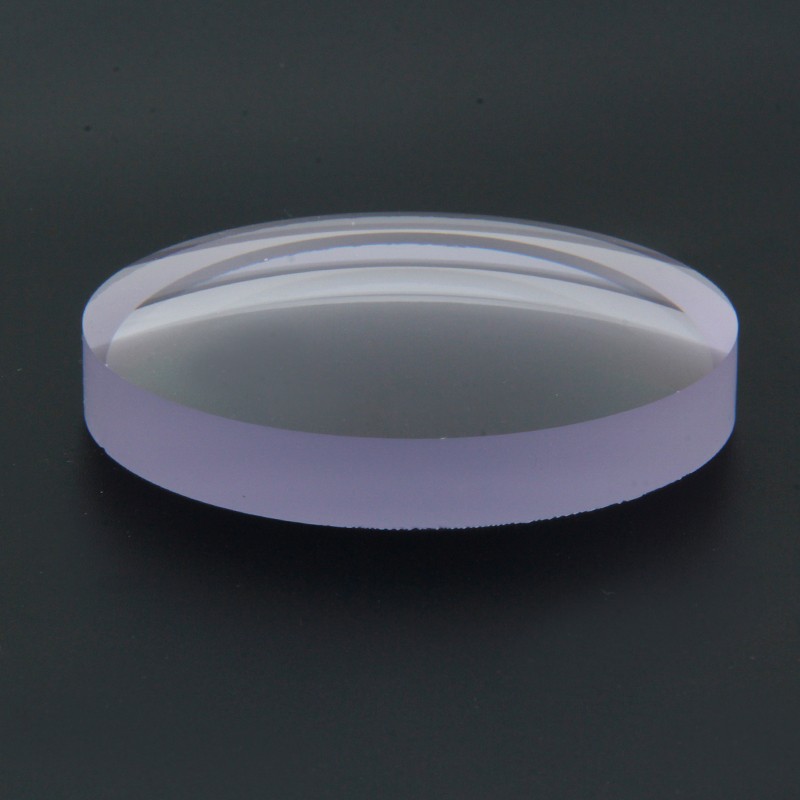

CR39 1.49 1.56 semi-finished UC/HC/HMC S/F lens

Products Description

|

Place of Origin:CN;JIA

|

Brand Name:

|

|

Model Number:1.49/1.56

|

Lenses Material:Resin

|

|

Vision Effect: Single Vision

|

Coating:UC/HC/HMC

|

|

Lenses Color: Clear

|

Diameter: 65/70/75mm

|

|

Abba Value:38

|

Specific Gravity:1.28

|

|

Transmittance:98-99%

|

Abrasion Resistance:6-8H

|

|

Coating Choice:UC

|

Index:1.499/1.49/1.501/1.552/1.56

|

|

Material:CR39 NK-55

|

Guarantee:1~2 Year

|

|

Delivery Time:Within 20 Days

|

RX Power available

|

Semi Finished Lenses

Semi-finished lens is the raw blank used to produce the most individualized RX lens according to thepatient’s prescription. Different prescription powers request for different semi-finished lens types or base curves.

The semi-finished lenses are produced in a casting process. Here, liquid monomers are first poured into moulds. Various substances are added to the monomers, e.g. initiators and UV absorbers. The initiator triggers a chemical reaction that leads to hardening or “curing” of the lens, while the UV absorber increases the UV absorption of the lenses and prevents yellowing.

–Hardness: One of the best quality in hardness and toughness, high impact resistance.

–Transmittance: One of the highest transmittance as compared with other index lenses.

–ABBE: One of the highest ABBE value providing the most comfortable visual experience.

–Consistency: One of the most reliable and consistent lens product physically and optically.

Hard coating: Make the uncoated lenses are easily subjicted and exposed to scratches

AR coating/Hard multi coating: Protect the lens effectively from reflection, enhance functional and charity of your vision

Super hydrophobic coating: Make the lenswaterproof, antistatic, anti slip and oil resistance

New anti-reflective coating

The new anti-reflective film layer has super anti-ultraviolet function, and can filter a large amount of stray light, enhance the imaging quality of the lens, and the imaging effect at night is better, which greatly improves the safety of night driving.

Scratches on lenses are distracting, unsightly and in certain conditions even potentially dangerous.

They can also interfere with the desired performance of your lenses. Scratch-resistant treatments toughen up the lenses making them more durable.

Unique optical concept design

Double non-design, lighter, thinner, wider field of vision, clearer vision.

360 ring focus peripheral vision control technology, no dead corners and no blind spots, relieve myopia deepening, and effectively correct vision.

Asymmetrical design + advanced “multiple design”, looking at far, middle and near in all directions.

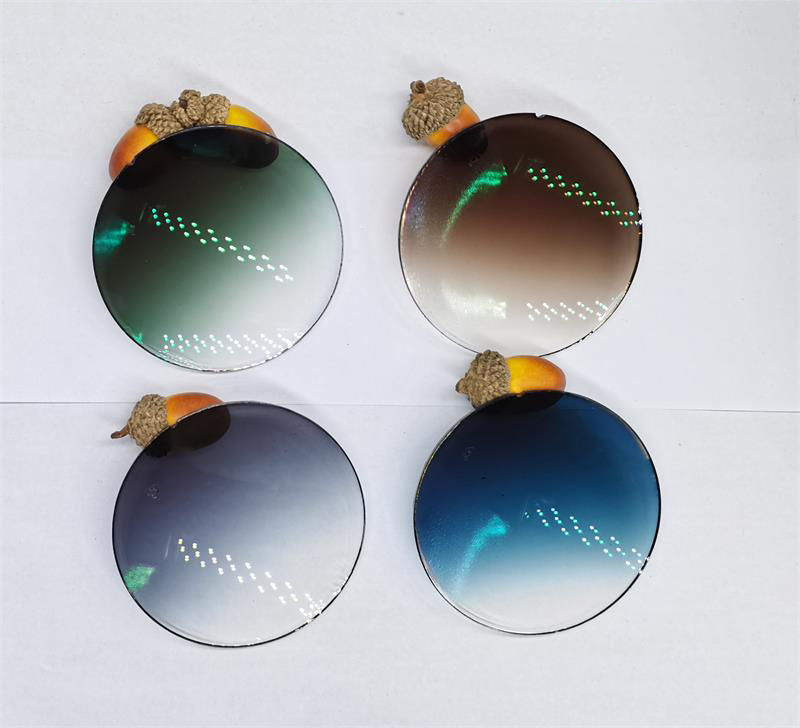

Different Color Coating To Choice.

Product Packaging

Shipping & Package

Production Flow Chart

About Us

Certificate

Exhibition

Our Products Testing

Quality Checking Procedure

FAQ