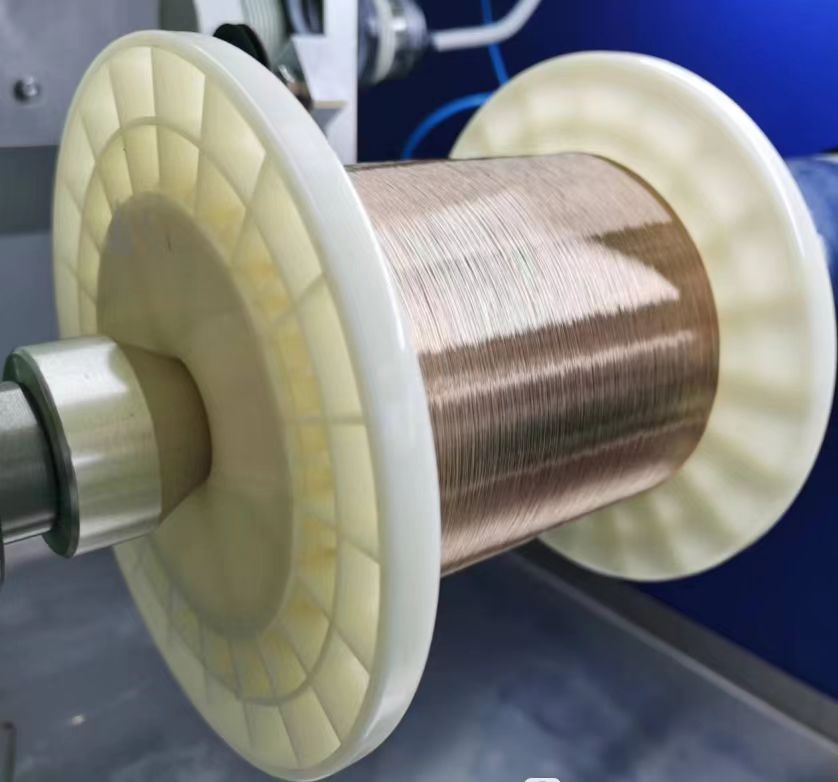

Copper Cobalt Beryllium Alloy Rod And Wire(CuCoBe C17500)

1. Chemical Composition of C17500

|

Model |

Be |

Co |

Ni |

Fe |

Al |

Si |

Cu |

|

C17500 |

0.4-0.7 |

2.4-2.7 |

- |

≤0.1 |

≤0.20 |

≤0.20 |

Remnant |

2. Physical And Mechanical Properties of C17500

|

State |

Performance |

|||

|

Standard Code |

Category |

Tensile Strength(MPa) |

Hardness(HRB) |

Electrical Conductivity(IACS,%) |

|

TB00 |

Solid Solution Treatment(A) |

240-380 |

Min50 |

20 |

|

TD04 |

Solid Solution Treatment & Cold Process Hardening State(H) |

450-550 |

60-80 |

20 |

|

|

After Heat Treatment Of Deposit |

|||

|

TF00 |

Heat Treatment Of Deposit(AT) |

690-895 |

92-100 |

45 |

|

TH04 |

Hardening & Deposit Heat Treatment of Settlement(HT) |

760-965 |

95-102 |

48 |

3. Application Fields of C17500

It is mainly used for fuse clips,fasteners,spring switches,relay parts.

Write your message here and send it to us