CNC Machining for Prototype and Low-Volume Projects

What Is Low-Volume Manufacturing?

Low-volume manufacturing is a specialized service that offers full production-quality parts but in volumes ranging from a single piece to a few thousand pieces. It’s ideal for moving an idea from the concept stage through prototyping, and from there as a bridge to full volume production.

Low volume production is considered to be a specialized service because most manufacturers don’t want to do it. Their assembly lines and supply chains are optimized for large production volumes that leverage economies of scale. There is nothing wrong with that approach, because it’s the best way to ensure the lowest cost per piece. However, it usually requires large minimum order volumes and a commitment to expensive tooling.

But what is a product developer to do if you want to start off with product volumes on the low end, from one part to one thousand? That’s where can help.

Benefits of Low-volume Manufacturing

Lower Tooling Costs

Work with companies like us who specialize in low-volume production. This can help you save on traditional mass production tooling costs and companies that aren’t willing to produce in low-volume quantities.

Improving your cash flow.

Shortening your time to production.

Buying time for production tooling to be finished.

Getting Products to Market Faster

Low-volume services can be a perfect step between prototyping and mass production. Getting your products to market faster than your competitors.

Improving your cash flow.

Shortening your time to production.

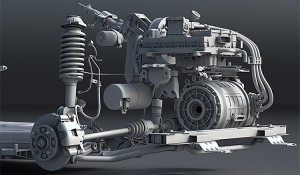

Low-Volume Casting

Low-volume metal castings are a cost-effective option to produce high-quality parts with a real feel and easy solution for complex geometries. is part of a small niche industry that specializes in low-volume castings.

Having a super-fast and responsive supplier that can supply your parts on-demand.

No import costs or hassles.

Lead Time & Capabilities

Lead times for our low production service vary from project to project. In most cases, volumes of 1-10,000 parts can be completed or begin deliveries in our standard lead time of 4-6 weeks. Depending on part complexity and expedite options, specific lead times can be brought in or pushed out from our standard lead time. Regardless of what the lead time is, you will be made aware of it at the time of the quote so you will know when parts will land on your dock.

Our high-speed machining capabilities help reduce cost and ensure consistency on production parts. We are constantly investing in the best production equipment, and we back it up with advanced metrology processes including optical inspection and 5-axis CMM technology.

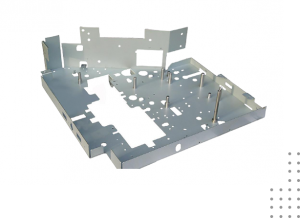

Our capabilities for low volume production are as follows:

● 5-Axis Milling

● CNC Milling

● CNC Turning

● Swiss Turning

● Wire EDM

● Waterjet Cutting