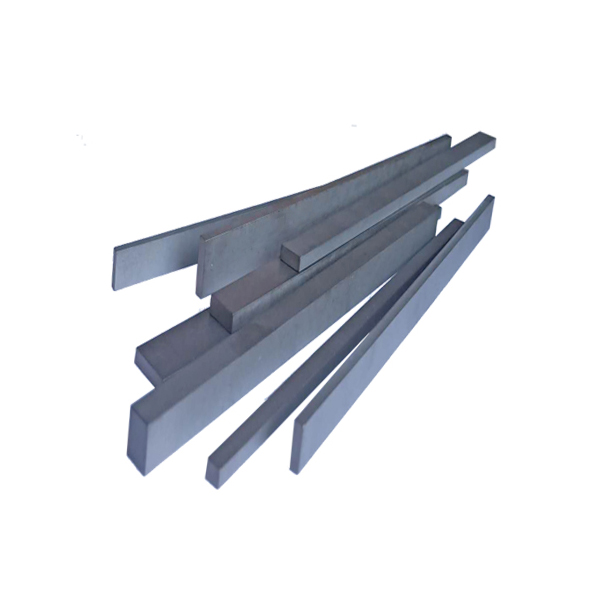

Cemented Carbide Strips

Cemented Carbide Strips

Cemented Carbide Plate(also named Tungsten Carbide strip) is a highly efficient and green material. Plates use scope are extremely widespread, widely used for woodworking, cutting metal, brazing tools and being mold materials. Carbide strips can also be used in many field as machining of refractory alloys, stainless steel, high manganese steel, for processing cast iron, non-ferrous metal and aluminum section bar, etc.

Cemented Carbide Strips are always suitable for making high temperature resistant parts, wear resistant parts, shielding parts and corrosion resistant parts. Our product will satisfy your cutting metal, wood and other materials application needs.

Features of Cemented Carbide Strips

Excellent high toughness, hardness, compressive strength; high wear resistance and impact resistance; good bending and stretching.

Superior heat stability, chemical stability, and thermal conductivity

Fine thermal shock resistance and anti-deformation in high temperature.

Good corrosion resistance, oxidation resistance, acid-base resistance from chemical

Long usage lifetime.

OEM/ODM, customization is available

Manufacturer supply, factory direct supply, nice price

ISO 9001 Certification

Recommend Grade of Cemented Carbide Strips

|

MY Grade |

MK05 |

MK20 |

MF30 |

|

|

Grade |

YG6X |

YG8 |

YG10 |

|

|

ISO Grace |

K10 |

K20 |

K20-K30 |

|

|

CO |

% |

6.3 |

8 |

10 |

|

Grain Size |

μm |

1 |

1.3 |

1.3 |

|

Density |

G/m³ |

14.8 |

14.7 |

14.5 |

|

Hardness |

HRA |

92 |

90 |

89.5 |

|

HV30 |

1610 |

1350 |

1300 |

|

|

T.R.S. |

Mpa |

2800 |

3000 |

3000 |

Other grades please click here and we can also offered by customs’ requirements.

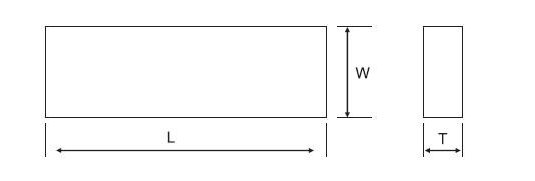

Dimension of Cemented Carbide Strips

Standard length is 330mm, inch standard and customized are available.

All in mm

|

Weight |

Tol. |

Thickness |

Tol. |

Length |

Tol. |

|

4.0 |

+0.2, +0.5 |

2.0-4.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

5.0 |

+0.2, +0.5 |

2.0-4.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

6.0 |

+0.2, +0.5 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

7.0 |

+0.2, +0.5 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

8.0 |

+0.2, +0.5 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

10.0 |

+0.2, +0.5 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

12.0 |

+0.2, +0.5 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

14.0 |

+0.2, +0.5 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

15.0 |

+0.2, +0.5 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

16.0 |

+0.2, +0.5 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

18.0 |

+0.2, +0.6 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

20.0 |

+0.2, +0.6 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

22.0 |

+0.2, +0.6 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

25.0 |

+0.2, +0.6 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

28.0 |

+0.2, +0.6 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |

|

30.0 |

+0.2, +0.6 |

2.0-6.0 |

+0.15, +0.5 |

330 |

0~+5.0 |