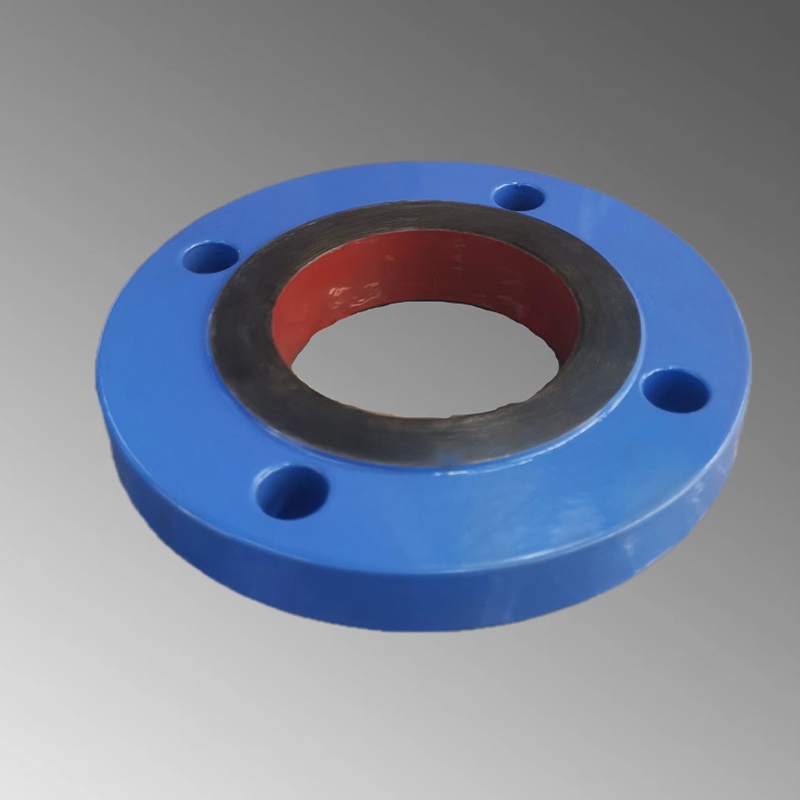

Alloy 400 Slip On Flange RF CLASS150

Product Introduction

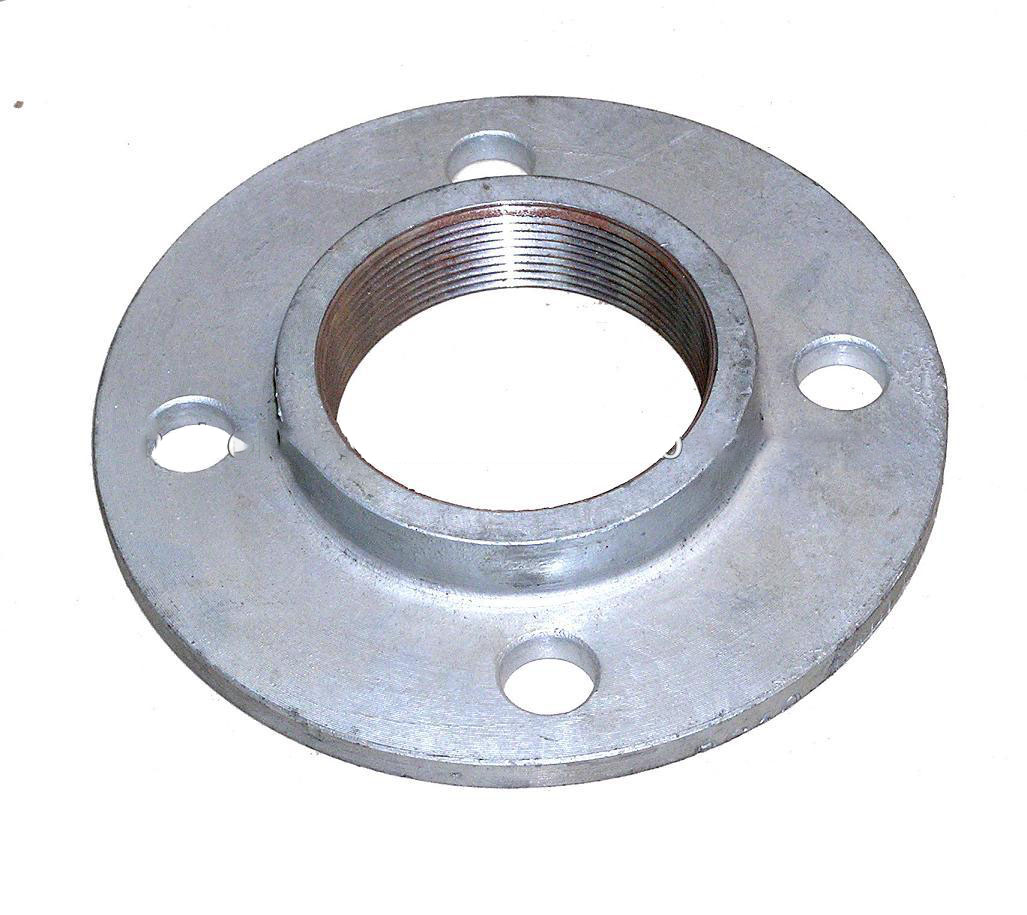

The other name of the neck flat welding flange is Slip On flange, which is a flange that extends steel pipes, pipe fittings, etc. into the flange and connects equipment or pipes through fillet welds.

Sealing Form

The sealing surface forms of Slip Onflange are:

Raised face (RF), concave face (FM), convex face (M), tenon face (T), grooved face (G), full face (FF).

Diameter range of neck flat welding flange: DN10~DN600.

Scope of Application

PN series PN2.5~PN40; Class series Class150~Class1500

Flange material: carbon steel, Luomo steel, 304, 316, 304L, 316L, 321, 347, CF8C.

About Advantages and Disadvantages

Advantages: The slip on flange is also neck slip on flange, because it has a short neck, which improves the strength of the flange and improves the bearing capacity of the flange.

Therefore, it can be used on pipes with higher pressure.

Disadvantages: The cost is higher than plate flat welding flange, and it is easier to bump due to its shape.

Dimension Data

About Alloy Steel

Alloy steel refers to alloy steel in which other alloy elements are added besides iron and carbon. An iron carbon alloy formed by adding one or more alloy elements on the basis of ordinary carbon steel.

According to the different elements added and the appropriate processing technology, high strength, high toughness, wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, non-magnetic and other special properties can be obtained.

(SLIP ON FLANGE ALLOY)

About Alloy 400

International name: Monlaloy400, UNSN04400, NICU30FEW-NR: 2.4360, Nicorros-Alloy 400, ATI400, NASNW400

Executive standards: ASTMB127/ASMESB-127, ASTMB163/ASMESB-63, ASTMB165/ASME SB-165

Main components: carbon (C) ≤ 0.30, nickel (Ni) ≥ 63.0, silicon (Si) ≤ 0.5, sulfur (S) ≤ 0.024, iron (Fe) ≤ 2.5, manganese (Al) ≤ 2.0.0, copper, copper(CU)28.0 ~34.0

Physical performance: density: 8.9g/cm3, melting point: 1300-1350 ° C, magnetism: none

Mechanical properties: tensile strength: σ B ≥ 480MPa, yield strength σ B ≥ 195MPa: expansion rate: δ ≥ 35%, hardness; Hardness; Hardness; Hardness;HB135-179

Corrosion resistance and main service environment: Alloy 400 is generally better than nickel and copper in corrosion resistance, and it is more resistant to pure nickel

The corrosion of recovery medium is better than that of pure copper oxidation medium, which is very useful for sulfuric acid, phosphate and carbon.

It is not the corrosion resistance of hydrochloric acid, but also has excellent corrosion resistance to hot alkali. Alloy 400 alloy has extremely high corrosivity in fluorescent mirror, hydrochloric acid, sulfuric

acid, sulfuric acid material performance, hydrofluoric acid and its schools. It is more resistant to corrosion than copper based alloys in seawater.