2000 Series Aluminum Plate Sheet-Aluminum Copper Alloy

Product Description

2000 series aluminum sheet: represents 2A16 (LY16), 2A06 (LY6). The 2000 series aluminum plate is characterized by high hardness, among which the original copper content is the highest, about 3-5%. 2000 series aluminum sheets belong to aviation aluminum materials, which are not often used in conventional industries.

2A16 aluminum plate is used in aerospace parts with a working temperature of 250~300 degrees Celsius, welding containers and airtight cockpits working at room temperature and high temperature.

2A06 aluminum plate is used in aircraft structures with a working temperature of 150~250 degrees Celsius and aircraft structure rivets with a working temperature of 125~250 degrees Celsius.

Physical and chemical properties of product grade

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al:Min. |

|

2A06 |

0.5 |

0.5 |

3.8-4.3 |

0.5-1.0 |

1.7-2.3 |

– |

0.1 |

0.03-0.15 |

the rest part |

|

2A16 |

0.3 |

0.3 |

6.0-7.0 |

0.4-0.8 |

0.05 |

– |

0.1 |

0.1-0.2 |

the rest part |

Specifications

| 1000 Series | Industrial Pure Aluminum(1A99, 1A97, 1050, 1050A, 1A50, 1060, 1070, 1350, 1145, 1035, 1100, 1200, 1235, 1A30) |

| 2000 Series | Aluminum-copper Alloys(2A01, 2A02, 2A04, 2A06, 2A11, 2A12, 2A14, 2A16, 2A17, 2A21, 2A25, 2A70, 2A80, 2A90, 2204, 2014, 2214, 2017, 2219, 2024, 2124) |

| 3000 Series | Aluminum-manganese Alloys(3A21, 3003, 3103, 3004, 3005, 3105) |

| 4000 Series | Al-Si Alloys(4A03, 4A11, 4A13, 4A17, 4004, 4032, 4043, 4043A, 4047, 4047A) |

| 5000 Series | Al-Mg Alloys(5A01, 5A03, 5A05, 5A06, 5B05, 5B06, 5A12, 5A13, 5A30, 5A66, 5005, 5019, 5050, 5251, 5052, 5154, 5454, 5754, 5056, 5456, 5082, 5083, 5182, 5183, In 5086) |

| 6000 Series | Aluminum Magnesium Silicon Alloys(6A12, 6B12, 6A51, 6101, 6005, 6060, 6061, 6063, 6063A, 6181, 6082) |

| 7000 Series | Aluminum, Zinc, Magnesium and Copper Alloys(7003, 7005, 7020, 7022, 7050, 7075, 7475, 7A01, 7A03, 7A04, 7A05, 7A09, 7A10, 7A15, 7A52) |

| 8000 Series | Other Alloys(8A06, 8011, 8090) |

Aluminum Grade

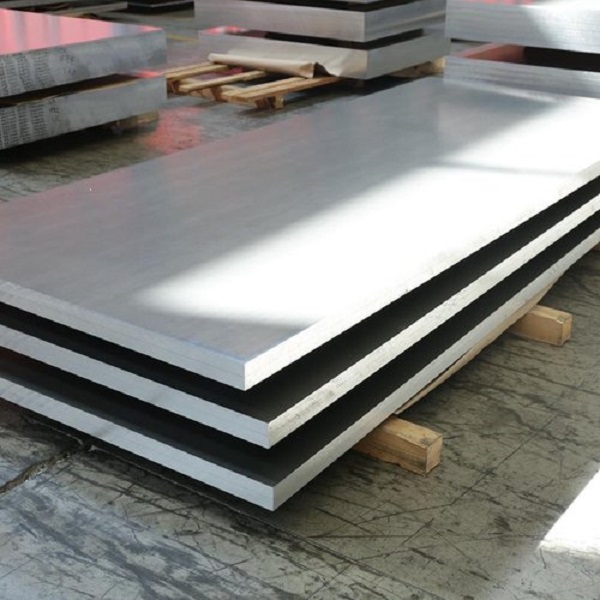

| Product name | Aluminum Sheet:0.15-6.0 Aluminum Plate:6.0-25.0 |

| Width(mm) | 20-2000mm or customized according to requirements |

| Thickness | 0.35mm-100mm or customized according to requirements |

| Length | According to the need to customize |

| Standard | GB, JIS, DIN, ASTM |

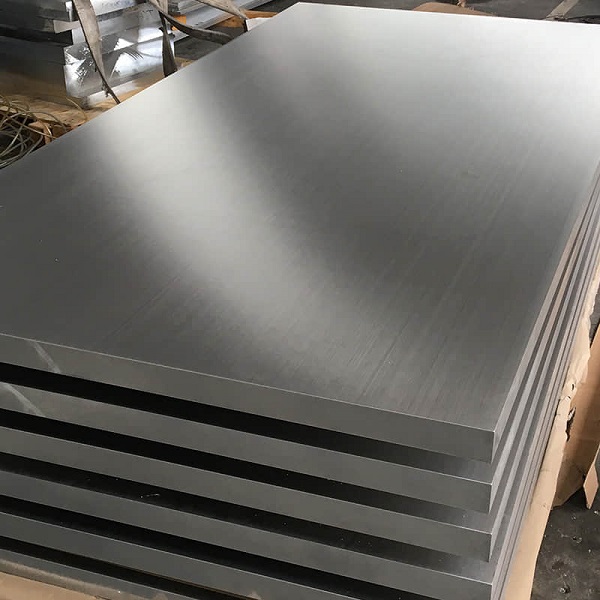

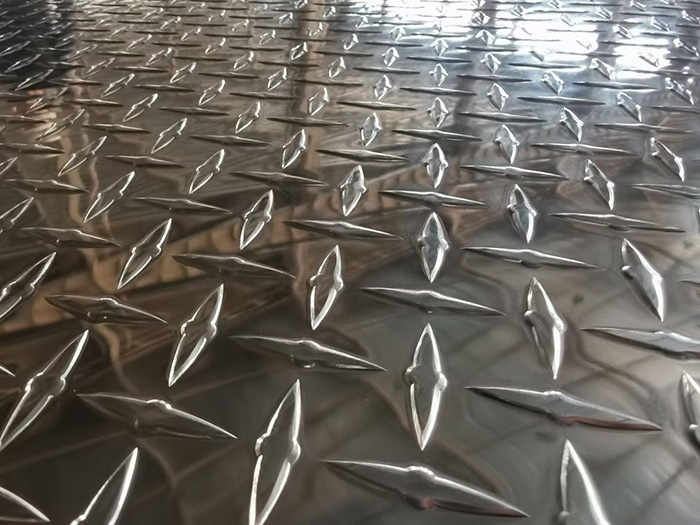

| Surface treatment | Bright, polished, hairline, brush, sandblasting, grid, relief, etching, rolling surface finish, no stains, no rough edges, patterns, printing,brushed, mirror, embossed, sandblasted, etc |

| Temper | O, H12, H14, H16, H18, H112, H113, H19, H111, H22, H24, H26, H211, H32, H36, H38, H131, H151, H241, H261, H341, H361, F, T53, T6, T63, T6351, T651, T73, T7351, etc. |

| Type | Plate, sheet,strips,belt, thin plate, medium plate, thick plate, super thick plate, coil |

| Properties | Corrosion resistance, heat resistance, high hardness, good ductility |

| Production process | Hot rolling or cold rolling |

| Product application | Industry, transportation, building modeling, automobile, medical machinery, etc |

| Package | Standard export package, such as wooden box or as required. |